Unique technology available to students free of charge on campus

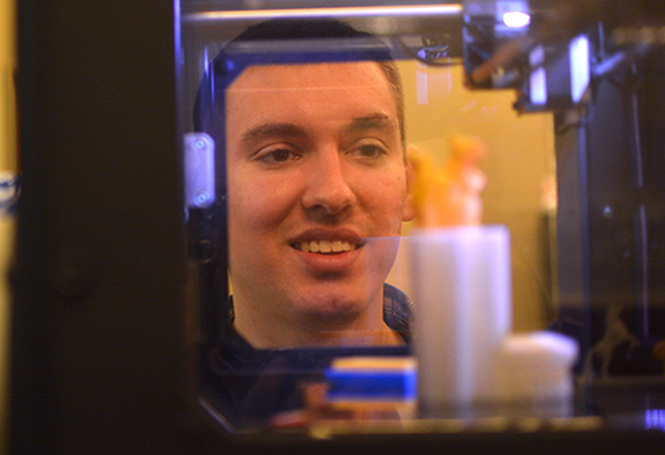

Kody Gann, senior technology major, watches items produced by the Kent State 3D on Sept. 14. Photo by Jacob Byk.

September 17, 2013

Upon walking into the library’s Student Multimedia Studio, the colorful plastic skulls, animals and bracelets that adorn its windows and desks are hard to miss.

For awhile, printing a flat picture has been easy and accessible. To create models, one might have to shape the object out of clay or go through a molding process.

Now, creating models can be as simple as printing out a report. Using one of the five 3-D printers Kent State currently hosts, students can now create physical objects based on three-dimensional models created on computers.

Two of these Makerbot Replicator 2X printers are available for students to use for free in the library’s Student Multimedia Studio and the Student Center’s Blackstone LaunchPad. This $2,800 machine can print in two colors.

The Student Multimedia Studio received itsprinter from a grant for Undergraduate Student Government. Michelle Crisler, senior integrated mathematics major and USG director of academic affairs, said USG had some extra money in the budget and voted to use it for the printer.

“We voted on the printer because we thought it was a good resource for students to have access to and that it was a smart way to use the extra money USG had,” Crisler said.

Hilary Kennedy, manager of the Student Multimedia Studio, said in the first two weeks of operation, the studio completed 12 orders, mostly for students experimenting with simple models — pre-created designs that they have downloaded from the internet.

“But we have already had discussions with several students who plan to 3-D print projects for class,” Kennedy said. “For example, various students in fashion, fine arts and architecture plan to create models and print them for course assignments.”

One of those students is Kai Wick, junior fine arts and crafts major. Wick is using the printer to make a mold for a class project — a water lily terrarium made of glass, plexiglass and metal. “Artists are using 3-D printing a lot more for mold creating and mass-producing,” Wick said. “ It’s really emotionally appealing if you have something of one or something of many and so, having the ability to have identical things repeated is really interesting.”

Wick’s piece is the largest project the library has endeavored. The 5-inch print will be used to mold a glass piece for the bottom of the terrarium. It will take 14 hours to print multiple pieces that will be glued together.

Blackstone Launchpad, Kent State’s entrepreneurial base, also purchased the same model of 3-D printer this summer. The printer, which is also free to use, is located in their offices in the Student Center.

Alisha Konya, senior computer science major and Launchpad’s 3-D adviser, said the machine could help entrepreneurs create prototypes of items they want to sell.

How to 3-D Print

Step 1: Users select a 3-D model to print. They can create their own model or download them from a website such as Thingiverse.

Step 2: Users open their designs in software, such as Makerware for Makerbots, and prepare their design for printing.

Step 3: Printing begins. Plastic printers such as the Makerbot and Cubify printers extrude hard plastic onto a hot plate, where it instantly hardens. It can take anywhere from a couple of minutes to a few hours, depending on size and complexity. Ceramic printers lay layers of clay or other materials in precise layers. These need time to dry.

Step 4: The object is ready.

“If they have an idea, they can actually physically see it,” Konya said. “It’s really good for fashion students, too, because any of the things they’re thinking of creating, they can see before they mass produce it.”

To help students learn how to use the printers, Konya will also host workshops that target different skill sets and interests, such as fashion.

“What I want to do at the workshops is explain what it is, because I don’t think people understand what you can do with it,” Konya said. “You can start with nothing and code an entire object or you can start with software that maybe have some preset shapes you can use and add them on top of each other.”

Despite — and perhaps because of — all its application, 3-D printing is not without its controversy. People have used the machines to print pieces of guns and drug paraphernalia. However, both Kennedy and Konya said they reserve the right to refuse designs they deem inappropriate.

Kent State also houses three other 3-D printers that are used for classes.

Architecture assistant professor Brian Peters owns two 3-D printers on campus, which he uses in his classes and in research. His lab has an Ultimaker and a RapMan, which prints using ceramics. He is also working on installing a robotic arm that can be used for 3-D printing.

Peters worked in the digital fabrication industry for two years and now researches how to use new materials with the printers. His project, Building Bytes, hopes to take small printed objects and make them into large-scale projects.

“There are so many applications in terms of architecture,” Peters says. “The idea of this project is to take the standard machine and figure out what you can make on a bigger scale. Hopefully, you can print a building.”

The craft department’s Jewelry, Metals and Enameling program also has a 3-D printer for use in their “CAD for Jewelry” class. Instructor Jessica Todd said the class focuses on creating jewelry using 3-D modeling. While this is not the first semester the class has been offered, it is the first semester they have a printer.

“In the past, students had to pay a lot of money and wait weeks to get their 3-D models back from outside companies,” Todd said. “If the models didn’t turn out as expected, they lost a lot of money and were often unable to reprint before the end of the semester. Now they can print models in a matter of hours and at a minimum cost.”

The Cubify Cube printer the class uses cost $1,300, and a class fee covers each student’s $50 printer cartridge. Todd said having the printer will give her students the unique experience that only comes with exploring new technology.

“They can hold in their hands something that they created on a flat screen.”

Lyndsey Schley is the senior enterprise reporter for the Daily Kent Stater. Contact her at[email protected].