The KnitLAB, which officially opened in June of this year, utilizes four high-tech digital knitting machines which students can utilize to help them in their classes and future careers.

“In the KnitLAB [students] can test the designs they programmed, knit some samples, or create pieces for their collections,” said Irina Milke Pavlova, second year master’s student and graduate instructor who works in the KnitLAB. “Or just to see and learn how to operate the knitting machine.”

The reasoning behind opening this resource was the increasingly expansive world of digital knitting that is impacting the fashion industry even at the university, said Pavlova.

“In our school we have a digital knitting course. Digital knitwork is a very fast-paced, fast-growing industry,” she said. “We are constantly developing our lab, purchasing new machines and new software.”

Additionally, the university has a nationally ranked fashion program, so there is an effort to stay on top of emerging trends in the industry.

“Our school is always trying to keep up with all of the industry related innovations,” Pavlova said. “I personally believe that digital knitting is the future of the fashion and textile industry.”

The high-tech machines in the KnitLAB can almost entirely operate on their own, they just require the help of an assistant to get started, Pavlova said.

“Technically the machine works as a 3D printer, so it requires an operator,” she said. “[An assistant] helps thread it, to manually control it, to manually control its interface. But it knits the piece itself.”

Students can put their designs into the machine via a USB, and the machine will knit for them, Pavlova said.

“You can even create a 3D garment with no seams,” she said. “You can produce a t-shirt or a sweater on this machine without any post-processing.”

The machines in the KnitLAB also create very little waste compared to traditional knitting machines.

“It is very sustainable,” Pavlova said. “The amount of waste is incomparable with the regular cut and sew technology. This machine technically produces no waste.”

The KnitLAB is open to all students across all majors who wish to learn more about the world of digital knitting.

“If someone really has an interest [in digital knitting], we want to help support that in any way possible,” Linda Ohrn-McDaniel, professor in the school of fashion and the faculty director of the KnitLAB. “So, working with students, working with people from off the street, people from industries and companies.”

There are also tutorials available, making it beginner-friendly for anyone who might have questions, Ohrn-McDaniel said.

“Anyone who is interested in knitting should come by,” she said. “We have tutorials if someone wants to try it out.”

The world of digital knitting is still being expanded upon, and more schools and companies are beginning to utilize this practice.

“Our school is one of a couple schools across the U.S. that offers a digital knitting program,” Pavlova said. “We are using the most innovative equipment that currently exists in the industry.”

As digital knitting expands in the fashion industry, it is also rising in popularity in other industries.

Digital knitting is popular in industries such as medical, automotive and aerospace, Pavlova said.

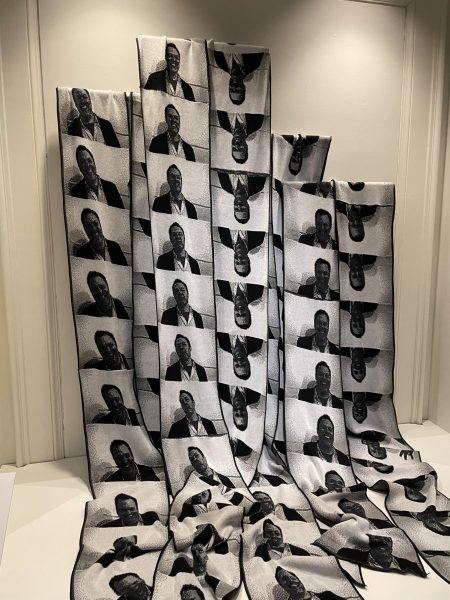

There is also an exhibit in the fashion museum called “Knitting Beyond the Body,” which shows visitors what is being done with digital knitting in all of these various industries.

The exhibit features knitted items such as sports equipment, Google Nest Minis, medical equipment such as braces and splints, chairs and clothing apparel.

“We want to be as open as possible to as many people as possible,” Ohrn-McDaniel said. “While we think of knitting initially from a fashion perspective, there are so many other areas that knitting goes into.”

Olivia Montgomery is a reporter. Contact her at [email protected].