Fashion/Tech Hackathon showcase innovative thinking

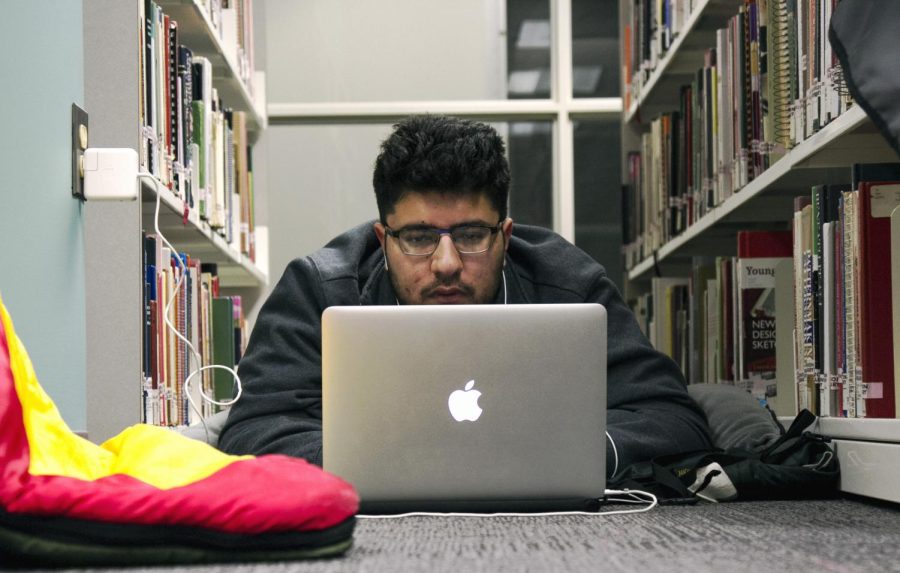

Computer engineering major, Madhur Malhotra, of the University of Pittsburgh, camps out on his sleeping bag while working on his team’s project in Rockwell Hall library on Jan. 30, 2016 as part of the Kent Hackathon.

January 31, 2016

The Fashion School at Kent State partnered with the university’s LaunchNET and the Fashion School’s TechStyleLAB to host the third annual Fashion/Tech Hackathon from Jan. 29 to Jan. 31 in Rockwell Hall.

More than 150 students, 87 of whom were first time hackers, competed in teams to create new and innovative products. Of those students, there was an equal ratio of men to women, according to Angela Wische, a senior fashion merchandising major and Fashion Hackathon volunteer.

The Hackathon serves as a way for students to come together to create new pieces of wearable technology and network with new people.

“A Hackathon is where new and original ideas are created mainly through the technology community, but what the Fashion Hackathon does (is creates) a merge between the two in order to have new innovative ideas in the retail environment and in general,” Wische said.

J.R. Campbell, director of the Fashion School, was involved with the creation of the Fashion School’s TechStyleLAB, which provided materials to hackers during the competition.

“When I first started here at the school as a director, one of the things I did was start to create the TechStyleLAB,” Campbell said. “The idea there was really just to bring all of the different digitally driven technologies that we can use in the context of fashion into one place and see what we can come up with,” Campbell said.

The teams of students worked together for 36 hours to create a new product to present at the end of the weekend.

Kent State sophomore fashion design major Brandon Yarchuk and junior fashion design major Joseph Barnett helped to create a heated jacket targeted at outdoor athletes that helps them train, but can also be worn for recreational use.

Yarchuk said the Hackathon is an interesting way for fashion and technology to come together.

“I like to see the two polar opposite ends of things,” Yarchuk said. “You have the artists and the design aspect and then the very technical aspect, and the fact that they can combine to create products that are actually utilitarian is so mething that’s fascinating to me.”

Junior fashion merchandising major Mary Jo Haley was involved with the creation of a sustainability website and app.

She said the Hackathon is an event with a creative environment.

“The Hackathon is so much fun, honestly, you come here and it’s all weekend, and you just learn so much,” Haley said.

This year’s Hackathon event featured an option for participants to use a 3D printer.

The use of 3D printing has been taking the world by storm since Charles Hull invented the machine in 1984. This revolutionary invention can be compared to Guttenberg’s printing press. It is a whole new way of manufacturing in the fashion world.

Campbell was enthusiastic about integrating the printer in this year’s Hackathon.

“Three-dimensional printing has all types of implications as you start thinking about it in the fashion industry as a whole,” Campbell said. “There is a lot of potential for doing very customized buttons, zippers, closures, components of garments and things that can be customized for preference or performance.”

According to digitaltrends.com, 3D printing is simply making a physical object from a virtual model. It’s very much like laser ink printers, except 3D printers use various materials, usually forms of plastic, to print layers on top of each other to create a three-dimensional form.

“This will definitely make things more accessible for people to be able to design their own things,” said senior digital sciences major Carrie Hadley. “It will also speed up the process of prototyping new things like smart watches.”

Three students from Case Western Reserve University, including electrical engineering major Derrik Best, took full advantage of the 3D printer during the Hackathon. Their team wanted to create a prototype for a self-tightening shoe. However, once arriving at Rockwell Hall, they realized that they did not have a mannequin’s foot to work with.

Best said he wanted people who may have mobility issues to be able to slide and adjust their shoes using gesture controls.

“The idea is that we want to create a shoe that is as easy to put on as a slipper, but when tightened up…it can provide the support of a walking shoe,” Best said. “Besides being able to market it simply for the novelty, there is also a need within people with certain disabilities or mobility issues who need help to put their shoes on and off.”

The Hackathon provides students the opportunity to create products that could help improve consumers’ lives.

“We wanted to create something that had a real purpose, and wasn’t just pretty to look at, something that had a purpose and could be used by people to help people,” said Chase Halbeck, a student from Case Western Reserve University.

With such an innovative idea, it proved very problematic for the team to be left without a model foot to work with. This is where Michael Nelson from Kent State’s LaunchNET program stepped in. Nelson was working at the Hackathon as the manager for one of the 3D printers in the building. He suggested the team find a 3D picture of a foot on the Internet to upload onto the printer and convert into a model foot.

“The print for the foot took maybe five hours,” Nelson said. “It was a women’s size 8 foot, so that’s a lot of plastic…but it cost probably $5 in plastic. The only downside is how long it took.”

The 3D printer came in handy for many other groups too. Nelson shared a sample of chain mail he and another group printed, as well as samples of closures a group printed for a dress. The Hackathon demonstrated how 3D printing has the potential be a prominent piece of technology throughout the future of fashion.

“It leads to more sustainable design and production, and less consumption,” Campbell said. “It’s a huge change on the prevailing business models that exist right now. It will potentially have a huge impact on the economy.”

To conclude the event, awards were presented the final day of the competition.

This year’s prizes were awarded in four categories: Creation of a New Technology, Advancement of an Existing Technology, Use of Technology in Creating New Fashion Products and Tech Advancement of the Retail Experience.

For the Creation of a New Technology category, Team Mirror Mirror won for inventing a smart mirror that allows consumers to virtually try on pieces of clothing from various stores.

In the Advancement of an Existing Technology category, Team All Time won for inventing memorable technology pieces, which included a watch for people suffering from Alzheimer’s disease.

Kent State President Beverly Warren attended the Hackathon for a second year in a row and spent time viewing students’ final project submissions.

“I’ve said it many times; I really think Kent State University students, we want them to be job creators, and we want them to be the innovators and creators of tomorrow,” Warren said. “This gives everyone a chance even while they’re still studying, to have prototypes of technology they can market. I really like that, and I think all of the learning experience is fabulous.”

Ile-Ife Okantah and Taylor Pierce are fashion reporters for The Kent Stater. Contact them at [email protected] and [email protected]