Culinary Services implements systems to reduce carbon footprint

January 25, 2023

In the fall, Kent State Culinary Services brought the PlanetOZZI system to campus, a reusable container system in the dining halls that promotes environmental friendliness.

The system has been successful so far, according to Casey Crane, assistant director of sustainability and purchasing for Kent State Culinary Services. She saw the system being used by other universities and knew it would be a great addition to campus.

PlanetOZZI’s reusable containers provide a closed-loop system that reduces a carbon footprint and water usage, as written on the company’s website. The system is considered to be “closed-loop” because once a user receives their first container, they do not need to purchase another.

“What you do at the beginning of the school year is pick up your first container and you go to the cashier at either of our all-you-care-to-eat dining facilities,” Crane said. “You tell them you have a meal plan and that you’d like to pick up your first OZZI container.”

Once a student has their initial container, they can fill it up with their food and take it to go. When they want to fill it up again, they can simply return their used container to the machine.

This system is available at the Eastway and DI Hub dining halls.

“You certainly don’t have to wash the container because we do all of that,” Crane said. “So you dump out the food, you bring it back to one of the dining halls and you put the container into one of the large black OZZI system machines. You put the barcode up, and the machine reads the barcode to check in that container, and then it prompts you to hit a button to get a little coin in exchange.”

When a user has their coin, they can take it to the desk attendant to receive a new container.

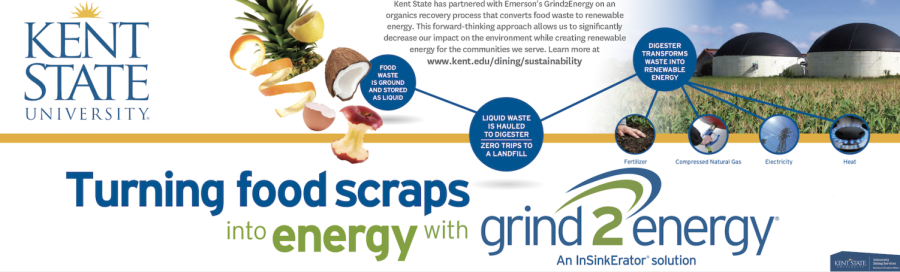

Kent State also has its Grind2Energy initiative.

Sommer Dunlevy, the assistant director of marketing for Culinary Services, said the university has struggled in the past to find a compostable vendor for food waste, which is what Grind2Energy targets.

“We’ve talked to several companies,” Dunlevy said, “but either there’s a concern that we have more volume than they can handle or we’re so far away from their compost piles that it’s not really a net positive when it comes to sustainability.”

The system shreds organic food waste, which is then moved into a large container and transported off campus.

“It only takes organic food matters, so it doesn’t allow for paper substrates, which is why we can’t put compostable disposables into it,” Crane said. “But if it’s food-organic matter, basically you run it through this large garbage disposal, grind it up into this pulp and put it into a pneumatic tube that is then squeezed out into a giant tank that is bigger than my office.”

After it leaves campus, the waste is taken to an anaerobic digester at a water treatment plant, providing energy to the water plant. It is used as fertilizer afterward.

Anthony Scilla is assistant photo editor. Contact him at [email protected].